Most modern companies have Reliability Engineers and reliability programs in place to improve maintenance and productivity outcomes. Typically, these programs will involve laser alignment during equipment installation and conditioning monitoring to optimise equipment availability. Both are time consuming and costly but they deliver quantifiable results and an increase in productivity and ROI. However, without a well-managed lubrication program supporting these programs the full advantages are not being gained. Bearing issues related to lubrication will be identified but unless an efficient lubrication program is implemented the problem will remain.

There are four primary components to grease lubrication for bearings:

- Lubricant selection

- Application method

- Re-lubrication volume

- Re-lubrication frequency

Correct Lubricant selection

Selecting the correct lubricant is critical but let us assume that this has been done as the technicalities of this are not the main subject of this topic. Systems that rely on hand greasing, or the lubricant replenishment of mechanical lubrication systems, introduce the possibility of the wrong grease being applied. The grease may not be suitable for the task or it may not be compatible with the grease already in the bearing, in both cases creating serious maintenance issues.

Application Method

Grease can be applied through centralised application systems, by hand-greasing with a grease gun and with single point automatic lubricators. Centralised systems are costly to install and maintain; they need to be refilled and require their own maintenance program. They are appropriate for some equipment types particularly where high grease volumes are needed but are not practical for many applications. For most types of equipment, the practical alternatives are usually hand lubrication or single point automatic lubricators. For equipment such as pumps, conveyors, electric motors, fans, screens, and most mining and processing equipment, a single point lubricator will provide the most cost effective and efficient result.

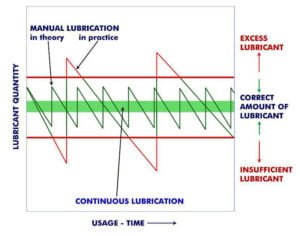

Manual greasing introduces the human element of uncertainty with respect to application of the correct grease, correct quantity, correct re-lubrication interval and possibly contamination issues from failing to ensure that equipment and fittings are free of contaminants before grease is applied. Hand greasing does not deliver the lubrication benefits of continuous lubrication: the bearings typically will have excess lubricant at the time of greasing and then reach a point where they are under-greased before the re-lubrication cycle catches up.

Manual greasing introduces the human element of uncertainty with respect to application of the correct grease, correct quantity, correct re-lubrication interval and possibly contamination issues from failing to ensure that equipment and fittings are free of contaminants before grease is applied. Hand greasing does not deliver the lubrication benefits of continuous lubrication: the bearings typically will have excess lubricant at the time of greasing and then reach a point where they are under-greased before the re-lubrication cycle catches up.

If vibration-monitoring equipment with “spike energy” or other high-frequency detection technology is being used, the grease input quantity can be optimised with the monitoring equipment. When the overall level of the signal drops noticeably as grease is being added, grease has reached the bearing.

Re-lubrication volume

With manual greasing, lubricant is generally applied until excess grease is seen coming out of the seals or the quantity is simply guessed at. Neither is a precise method providing a suitable outcome that optimises the benefits of the condition monitoring program. Some bearing companies provide formulas for re-lubrication however these are theoretical with respect to the amount of grease that is actually needed and usable in the rolling elements, and don’t take all factors into account. The type and age of existing grease, housing types, operating conditions, factors such as speed, load and vibration may all mean that this theoretical approach is unsuitable. A continuous lubrication method established on a condition-based approach will provide a better outcome. If condition monitoring is already used then the results of what will probably be a lower, but correctly applied grease input, compared to manual lubrication, and with a superior outcome, can be easily and accurately verified.

Re-lubrication frequency

Factors such as bearing type, seal type, bearing and seal condition, temperature, water contamination, load, vibration, particle contamination and grease quality will all influence the re-lubrication frequency. In practice it will be difficult with hand greasing to put in place a program that accounts for all of these factors and also is practical in terms of human resources, the necessary hand greasing cycle and equipment operation.

GreaseMax lubricators provide a cost effective and efficient solution to these lubrication issues and optimise the benefits of a Condition Monitoring program. For further information about GreaseMax application please contact Delta International Sales.